What is Geotextile fabric? – Types and Uses

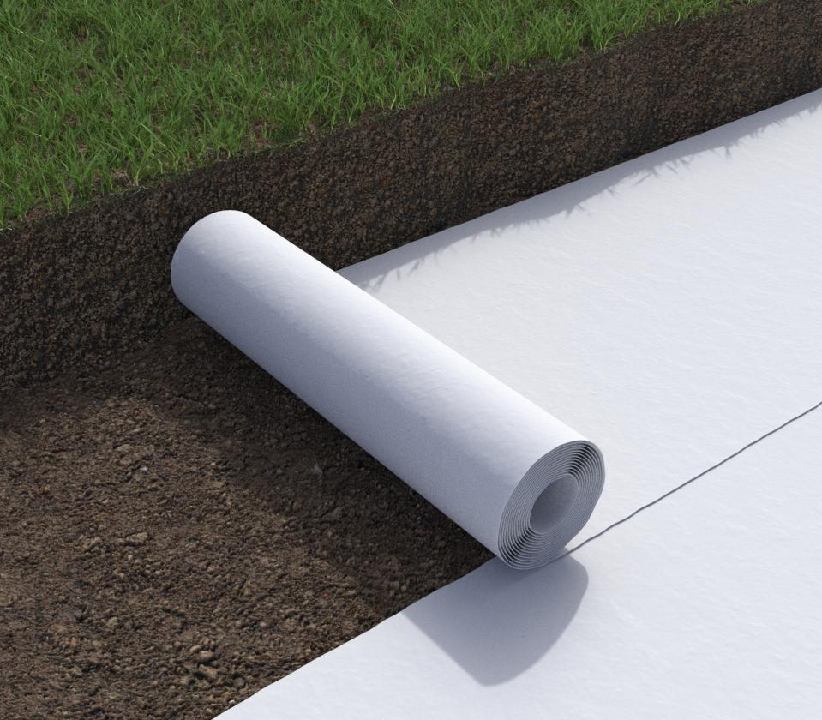

Geotextiles, or geotextile membranes, are permeable fabrics that are used to reduce erosion and maintain soil stability, usually for conservation or agricultural objectives. To fortify the soil, the ancient civilization used natural plant fibres into it, but since the 1950s, synthetic polymers have been employed to make modern geotextiles.

Types of geotextiles

Made for practical applications, geotextiles come in several varieties to suit different requirements.

- Non-woven geotextile

Nonwoven geotextiles are used to prevent erosion and to keep backfill materials in place. The non-woven geotextile is made up of polypropylene or polyester fibres that are either oriented or randomly patterned in a sheet, similar to felt, and then needle punched to create a strong, malleable textile with outstanding elongation capabilities. When subjected to wear and tear, the needle punching helps to keep the geotextile from delaminating. Nonwoven geotextiles are permeable to water and air, allowing them to travel freely through or within them. They are resistant to both wet and dry circumstances, and they do not rot or get fungus-infected. Most chemicals, as well as soil acid and alkalis, are resistant to geotextiles. Geotextile comes in a range of thicknesses, weights, and colours.

- Woven geotextile

Woven geotextile is utilised in a variety of civil engineering and construction projects. Woven geotextile is made from polypropylene or polyester strip fibre and has high strength in both directions. Because of its great strength, the fabric has an outstanding weight-to-strength ratio and is resistant to UV radiation, soil pollutants, mildew, and insects. Geotag woven geotextile is a great separator that is simple to install for road, building, and embankment applications. Because it extends the life of both paved and unpaved regions, this product is suitable for road construction. Woven geotextiles are commonly used for separation, reinforcement, and filtration.

Uses of geotextiles

When it comes to designing and construction projects, geotextiles are an excellent choice since they have unique qualities that provide economic benefits, such as less material usage and quick and easy installation. They’re commonly utilised in the following situations:

- Road worksGeotextiles are frequently used in road construction. It adds tensile strength to the soil, thus strengthening it. The geotextiles must maintain their permeability while maintaining their separating functions since they are utilised as a quick dewatering layer in the roadbed.

- Railway works

When the ground is unstable, woven or non-woven materials are employed to divide the soil from the subsoil without obstructing groundwater movement. Individual layers are encased in cloth to prevent them from swaying sideways due to shocks and vibrations from passing trains

- Agriculture

It’s used for mud control. Nonwoven fabrics are used to improve muddy roads and trails used by cattle or light traffic. They are folded by overlapping to hold a pipe or a mound of grit.

- Water drainage

The use of geotextiles to filter soil and a more or less uniform granular material to convey water is increasingly being considered as a technically and practically feasible alternative to traditional methods. Geotextiles are used to filter drainage in earth dams, on roads and highways, in reservoirs, behind retaining walls, in deep drainage ditches, and in farming.

- Coastal Works, Canals, and Rivers

Revertments and banks are protected by geotextiles from erosion caused by currents or lapping. When used with natural or artificial stone layers, they act as a filter.

Functions of geotextiles

Four discrete functions define the mode of functioning of a geotextile in any application;

- Separation

Geotextiles are commonly used in road construction because of their separating properties. Geotextiles could prevent the intermixing of two neighbouring soils. The geotextile, for example, retains the drainage and strength characteristics of the aggregate material by separating fine subgrade soil from the aggregates of the base course.

Some of the applicable areas are:

- Between subgrade and stone base on unpaved and paved roads and airfields.

- Between subgrade in railroads.

- Between landfills and stone base courses.

- Between geomembranes and sand drainage layers.

- Filtration

The geotextile-to-soil system equilibrium provides adequate liquid flow with little soil loss across the geotextile’s plane. The key features of geotextiles that involve infiltration action are porosity and permeability.

- Reinforcement

In the same way that steel raises the tensile strength of concrete, geotextile increases the tensile strength of the soil. The following three mechanisms account for the increase in soil strength as a result of the installation of geotextiles.

- Interfacial friction between the geotextile and the soil/aggregate provides lateral constraint.

- Forcing a greater shear strength surface to grow on the possible bearing surface failure plane.

- Membrane type of support for the wheel loads.

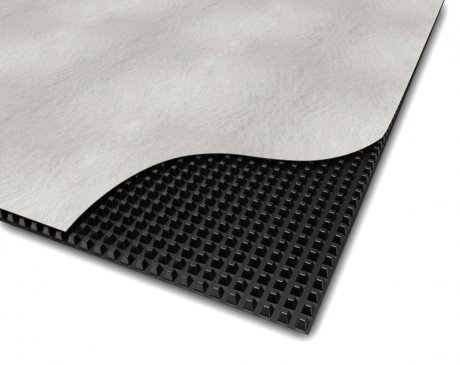

- Sealing

A layer of non-woven geotextile is placed between the existing and new asphalt layers. The geotextile absorbs asphalt and transforms into a waterproofing membrane, preventing water from flowing vertically into the pavement structure.

Wall Tag is one of the leading suppliers of various types of geotextile membranes in Singapore with a strong sales and service network availability to cater to their clients.

Visit Wall Tag and get to know about geotextiles.